Brand:

CORIGY SOLARItem NO.:

FRM-004Payment:

T/T, L/C, O/A, D/PProduct Origin:

CHINAShipping Port:

XIAMENLead Time:

Depends on project time or receipt time

Cement Foundation Solar Panel Ballast Mounting System

Rooftop ballasted systems can be used on a variety of flat or low-slope rooftop surfaces, including concrete, EPDM, TPO, PVC, and other membrane types. They are also suitable for locations with specific roofing restrictions or limitations.

Install Site

Tilt Angle

10~60 Degree

Building Height

20 m

Max Wind Speed

<60m/s

Snow Load

1.4KN/m2

Standard

Material

High Class Aluminum Alloy Al6005-T5 & Stainless Steel 304

Anticorrosive

Anodized Aluminum & Stainless Steel

Color

Natural and Customized

Warranty

Flat Roof or Lower Profile Roof

AS/NZS 1170 and Other International Standard

Ten Year Warranty and Twenty Year's Service Life

How much ballast do I need for solar panels?

Ballast systems for solar panels are designed to provide sufficient weight to counteract the uplift forces caused by wind. The ballast is typically in the form of concrete blocks, stone, or other heavy materials that are placed on the racking system to keep it stable and prevent it from being lifted or moved.

The amount of ballast required for solar panels depends on several factors, including the size and weight of the panels, the wind speed and site-specific conditions, and the mounting system being used. Generally, ballast amounts are calculated to ensure the stability and safety of the solar array. It is typically expressed as a weight per square foot or square meter.

It is important to consult with a professional solar installer or structural engineer who can analyze your specific installation circumstances and provide accurate calculations for the required amount of ballast. Corigy's engineer team can do it.

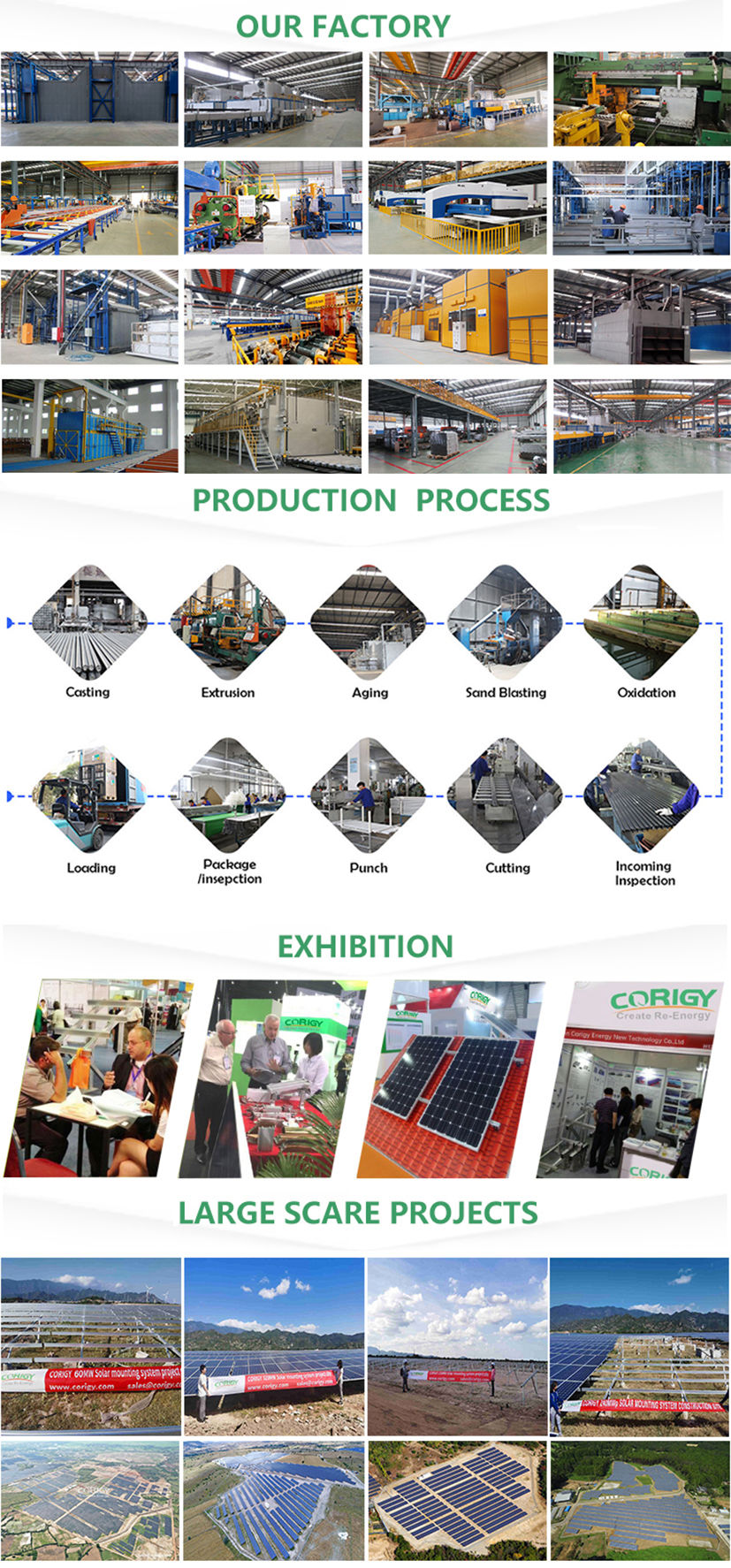

Corigy

Solar has been focusing on manufacturing and design solar mounting

bracket for more than 10 years. Corigy's products have been installed

and used in more than 30 countries and regions, with a total installed

capacity of more than 8GW. After the construction is completed, all

projects are completed by the official acceptance team, and they are

currently officially put into operation.

In

terms of selection, Corigy is based on the principle of highest

quality. The bracket uses high-quality main materials high-grade anode

aluminum Al6500-T5. The surface uses anode oxidation 12-15mic. Excellent

anti-corrosive rust and anti-rust performance ensures its 30-year

service life. At the same time, the characteristics of aluminum

lightweight reduces the weight of the roof and make it safe and

reliable. The maximum wind speed can carry 60m/s, and the snow load

capacity is 1.4kn/㎡.

All

bracket solutions of Corigy are calculated based on the live conditions

environment. Corigy's advanced technical team conducted a force

analysis of the structure of the building, combined with the layout of

the bracket and photovoltaic components to verify the various feasible

bracket installation solutions to determine the most efficient,

convenient, safe and reliable solution.