Brand:

CORIGY SOLARItem NO.:

FRM-007Payment:

T/T, L/C, O/A, D/PProduct Origin:

CHINAShipping Port:

XIAMENLead Time:

Depends on project time or receipt time

East West Ballast Flat Roof Solar Mounting System

|

Install Site |

Flat Roof or Lower Profile Roof |

|

Tilt Angle |

10~60 Degree |

|

Building Height |

20 m |

|

Max Wind Speed |

<60m/s |

|

Snow Load |

1.4KN/m2 |

|

Standard |

AS/NZS 1170 and Other International Standard |

|

Material |

High Class Aluminum Alloy Al6005-T5 & Stainless Steel 304 |

|

Anticorrosive |

Anodized Aluminum & Stainless Steel |

|

Color |

Natural and Customized |

|

Warranty |

Ten Year Warranty and Twenty Year's Service Life |

1. Ballasted Racking System: This method involves using a ballast, typically made of concrete blocks or steel weights, to secure the solar panels in place. The racking system is designed to distribute the weight evenly across the roof. The ballast provides enough weight to anchor the system without penetrating the roof. This method is non-penetrating, meaning it does not require any holes to be drilled into the roof surface. It is often used in commercial or large-scale installations.

2. Mechanical Attachment: Another method is to mechanically attach the solar panels to the roof using mounting brackets and fasteners. This approach requires penetrating the roof membrane and securely attaching the panels to the structural framing of the building. It is important to take proper precautions to avoid damaging the roof and ensure proper waterproofing to prevent any leaks. The specific attachment method may depend on the type of flat roof (e.g., concrete, metal, or membrane) and local building codes.

3. Adhesive Mounting: Some flat roofs allow for the use of adhesive systems, where the solar panels are attached directly to the roof surface using specialized adhesives. This method eliminates the need for penetrations and is often used on roofs made of materials like single-ply membranes or certain types of metal roofs. Manufacturers of adhesives provide guidelines for proper installation to ensure a secure bond.

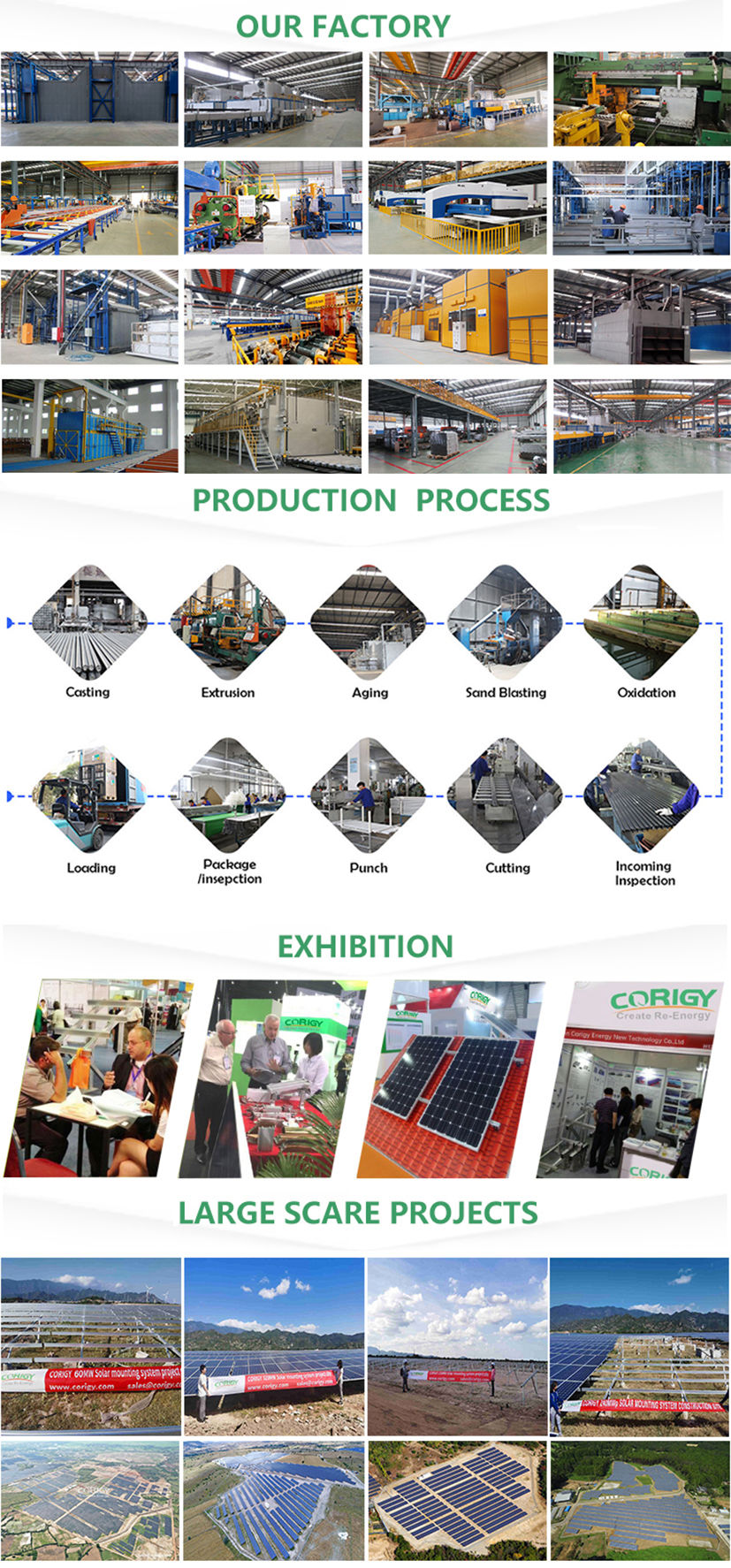

Corigy

Solar has been focusing on manufacturing and design solar mounting

bracket for more than 10 years. Corigy's products have been installed

and used in more than 30 countries and regions, with a total installed

capacity of more than 8GW. After the construction is completed, all

projects are completed by the official acceptance team, and they are

currently officially put into operation.

In

terms of selection, Corigy is based on the principle of highest

quality. The bracket uses high-quality main materials high-grade anode

aluminum Al6500-T5. The surface uses anode oxidation 12-15mic. Excellent

anti-corrosive rust and anti-rust performance ensures its 30-year

service life. At the same time, the characteristics of aluminum

lightweight reduces the weight of the roof and make it safe and

reliable. The maximum wind speed can carry 60m/s, and the snow load

capacity is 1.4kn/㎡.

All

bracket solutions of Corigy are calculated based on the live conditions

environment. Corigy's advanced technical team conducted a force

analysis of the structure of the building, combined with the layout of

the bracket and photovoltaic components to verify the various feasible

bracket installation solutions to determine the most efficient,

convenient, safe and reliable solution.