Brand:

CORIGY SOLARItem NO.:

FRM01Payment:

T/T, L/C, O/A, D/PProduct Origin:

CHINAShipping Port:

XIAMENLead Time:

Depends on project time or receipt timeFlat Roof East West Solar PV Mounting Ballast

Aluminum flat roof solar bracket, also known as a flat roof solar mount or flat roof solar racking system, is a structure designed to securely mount solar panels on a flat or low-sloped rooftop. Flat roofs are commonly found on residential and commercial buildings, and utilizing them for solar panel installations can be an efficient way to generate renewable energy.

|

Install Site |

Flat Roof or Lower Profile Roof |

|

Tilt Angle |

10 Degrees |

|

Building Height |

20 m |

|

Max Wind Speed |

<60m/s |

|

Snow Load |

1.4KN/m2 |

|

Standard |

AS/NZS 1170 and Other International Standard |

|

Material |

High Class Aluminum Alloy Al6005-T5 & Stainless Steel 304 |

|

Anticorrosive |

Anodized Aluminum & Stainless Steel |

|

Color |

Natural and Customized |

|

Warranty |

Ten Year Warranty and Twenty Year's Service Life |

What is a ballasted racking system for solar?

A ballasted racking system for solar also known as a ballast mounting system, is a type of solar panel installation method that utilizes the weight of the system and the force of gravity to secure the solar panels to the ground or roof.

Unlike traditional mounting systems that rely on penetrations or attachments to the surface, ballasted racking systems do not require anchoring. Instead, they use heavy objects known as ballasts to provide stability and keep the solar panels in place. Ballasts typically consist of concrete blocks or specially designed weights that are placed on the racking system or directly on the ground.

Benefits of ballasted racking systems include:

1. Easy installation: Ballasted systems are relatively quick and easy to install compared to other mounting methods, such as roof attachments. They typically require fewer tools and labor, simplifying the installation process.

2. No roof penetrations: Unlike other mounting systems that require drilling holes in the roof, a ballasted system does not penetrate the roof surface. This helps preserve the integrity of the roof and reduces the risk of leaks or damage.

3. Versatility: Ballasted systems can be used on various surfaces, including flat roofs, gravel roofs, and even on the ground.

4. Flexibility: Ballasted racking systems offer flexibility in terms of system design and panel layout. Solar panels can be easily reconfigured or relocated if needed, making it an ideal choice for buildings with changing needs or lease agreements.

4.Reduced maintenance: Since ballasted systems do not penetrate the roof or ground, they require minimal maintenance and are less likely to cause leaks in roofing systems.

1. Fix the rear legs and front leg on the ballast rails

2. Place the ballast trays on the ballast rails. And place the concrete blocks on the ballast trays. FRM03 need to install the rail

3. Fix the panel on the rear legs and front legs with middle/end clamps

4. Install the other side for east-west design

5. Install the rail connectors on the ballast rails to connect with other arrays

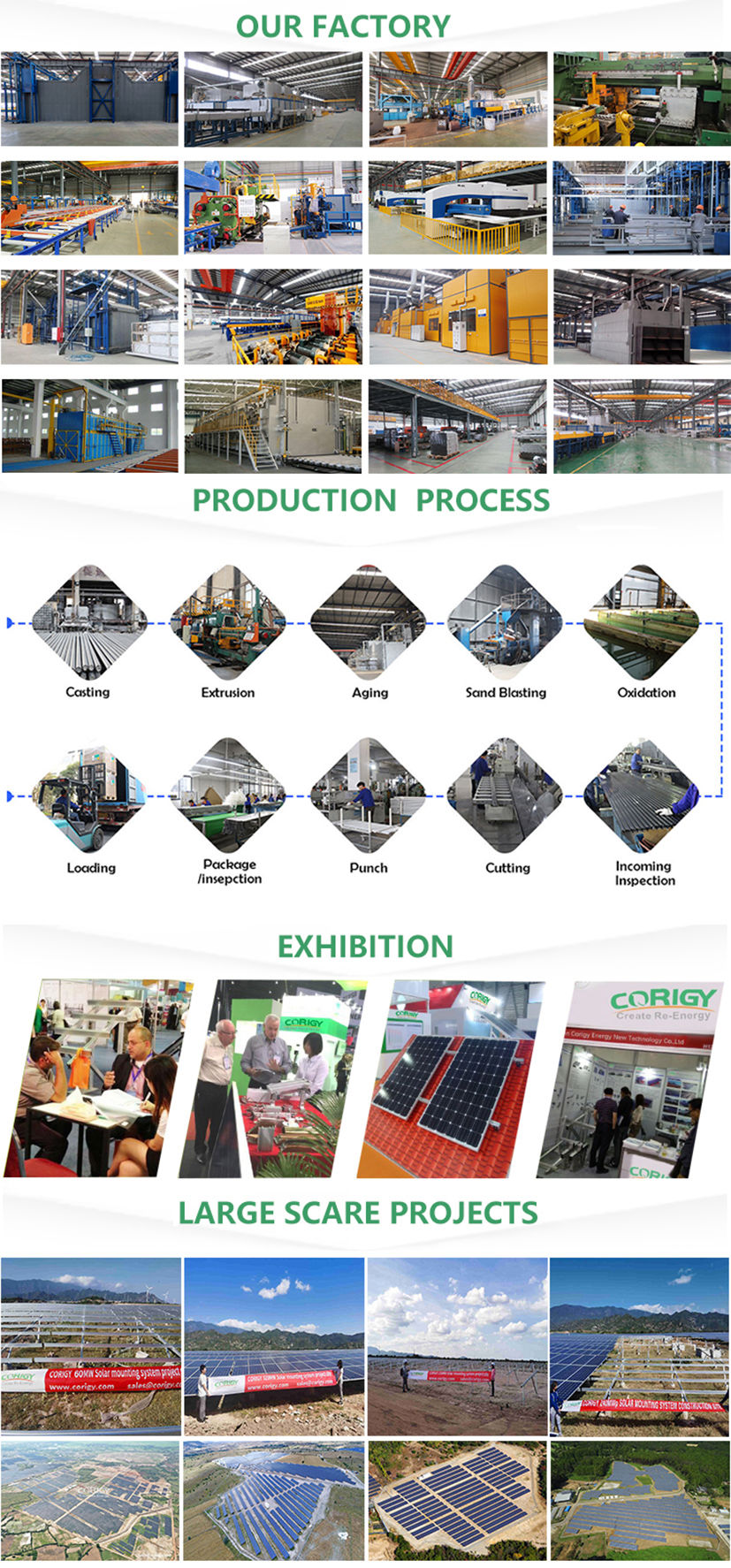

Corigy

Solar has been focusing on manufacturing and design solar mounting

bracket for more than 10 years. Corigy's products have been installed

and used in more than 30 countries and regions, with a total installed

capacity of more than 8GW. After the construction is completed, all

projects are completed by the official acceptance team, and they are

currently officially put into operation.

In

terms of selection, Corigy is based on the principle of highest

quality. The bracket uses high-quality main materials high-grade anode

aluminum Al6500-T5. The surface uses anode oxidation 12-15mic. Excellent

anti-corrosive rust and anti-rust performance ensures its 30-year

service life. At the same time, the characteristics of aluminum

lightweight reduces the weight of the roof and make it safe and

reliable. The maximum wind speed can carry 60m/s, and the snow load

capacity is 1.4kn/㎡.

All

bracket solutions of Corigy are calculated based on the live conditions

environment. Corigy's advanced technical team conducted a force

analysis of the structure of the building, combined with the layout of

the bracket and photovoltaic components to verify the various feasible

bracket installation solutions to determine the most efficient,

convenient, safe and reliable solution.