Brand:

CORIGY SOLARItem NO.:

TRH29Product Origin:

CHINAColor:

SilverShipping Port:

XIAMENLead Time:

Depends on project time or receipt time

Stainless steel solar hooks are specialized mounting hardware used for installing solar panels on roofs. As the name suggests, these hooks are made from stainless steel, which is known for its durability and resistance to corrosion, making it ideal for outdoor applications.

|

Product Name |

Stainless Steel Hook |

|

Mount Location |

Sloped Roof |

|

Mount Base |

Arched ceramic tile roof |

|

Mount Angle |

Parallel to the rooftop |

|

Wind Load |

60m/s |

|

Snow Load |

1.6KN/m2 |

|

Applicable Solar Panels |

Framed Panels & Frameless Panels |

|

Solar Panel Layout |

Horizontal Panel Installation & Vertical Panel Installation |

|

Design Standard |

AS/NZS 1170 , DIN 1055 ,JIS C8955 2017 |

|

Rack Material |

Al6005-T5 (Surface Anodic Oxidation) |

|

Fastener Material |

SUS304/SUS410 |

|

Mounting Accessories Material |

Al6005-T5 (Surface Anodic Oxidation) |

|

Column color |

Natural Silver or According to Customer |

|

Warranty Period |

10 years |

|

Service Life |

25 years |

|

Loading Port |

Xiamen Port,China |

How do you fasten solar panels to a roof?

One common method for fastening solar panels to a roof is to use stainless steel solar hooks. These hooks are designed specifically for solar panel installations and are typically made of corrosion-resistant stainless steel to ensure long-lasting durability. Here's a general overview of the process:

1.Roof Inspection: Before installing solar panels, it's important to assess the condition of the roof and ensure it's structurally sound. An inspection can help identify any repairs or reinforcements needed.

2. Racking System: Solar panels are typically mounted on a racking system that provides support and allows for adjustments. The racking system is usually made of aluminum or stainless steel.

3.Attachment Points: Stainless steel solar hooks are used as attachment points between the racking system and the roof. These hooks are specifically designed to penetrate the roof surface without compromising its integrity.

4. Roof Flashing: To create a waterproof seal around the hooks, roof flashing is installed. Flashing typically consists of a metal plate or rubber material that is placed over the hooks and secured to the roof.

5. Secure Fastening: The solar hooks are securely fastened to the roof using screws or bolts. The type of fasteners used depends on the roof type and the manufacturer's recommendations.

6. Racking Installation: Once the solar hooks are in place, the racking system is mounted onto the hooks. The alignment and positioning of the racking components should be carefully adjusted to ensure optimal orientation and spacing for the solar panels.

7. Panel Installation: After the racking system is secured, the solar panels can be mounted onto the racking using clamps or brackets provided by the manufacturer. The panels are typically attached to the racking rails in a predetermined configuration.

According to different roof shapes, choose the matching photovoltaic shingle roof hook

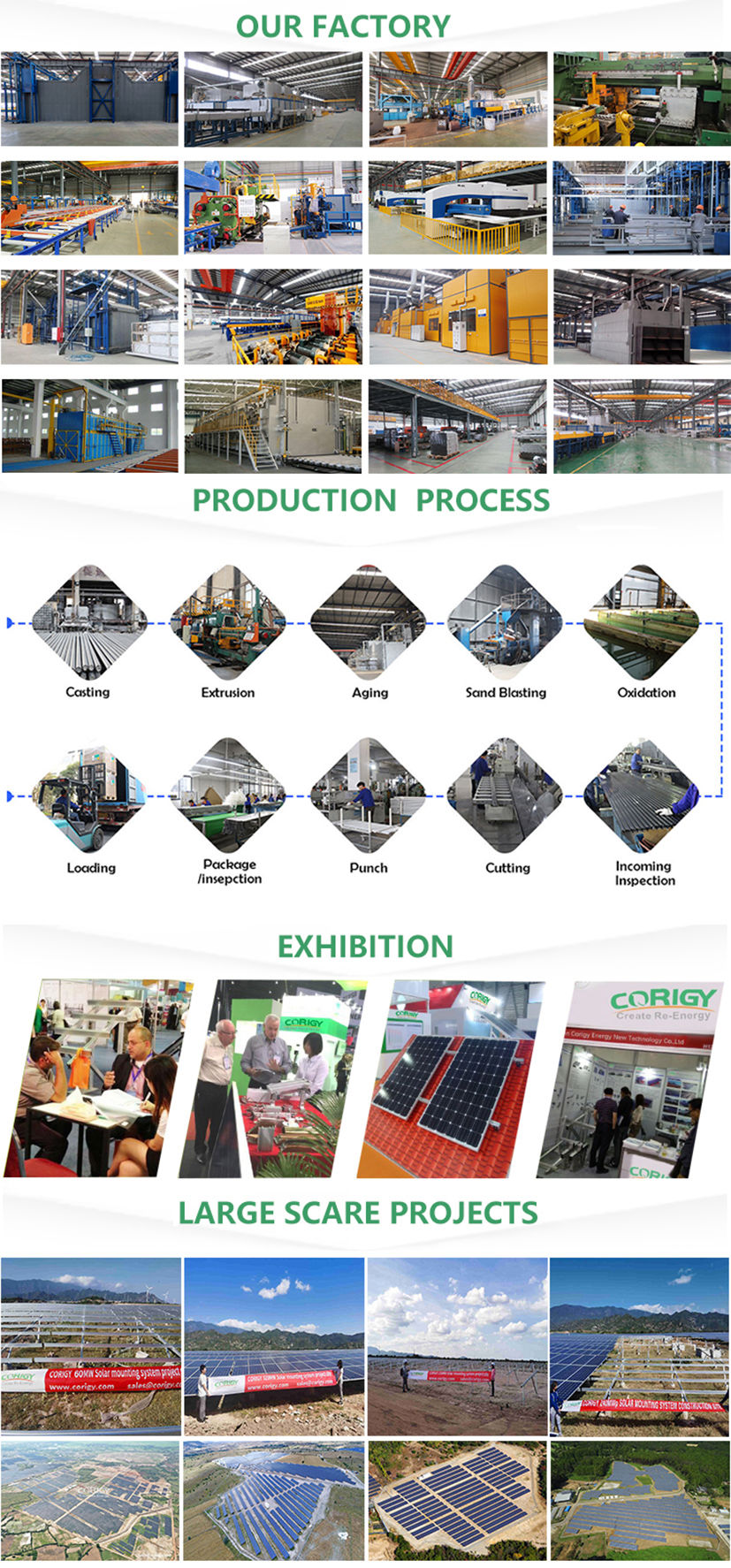

Corigy

Solar has been focusing on manufacturing and design solar mounting

bracket for more than 10 years. Corigy's products have been installed

and used in more than 30 countries and regions, with a total installed

capacity of more than 8GW. After the construction is completed, all

projects are completed by the official acceptance team, and they are

currently officially put into operation.

In

terms of selection, Corigy is based on the principle of highest

quality. The bracket uses high-quality main materials high-grade anode

aluminum Al6500-T5. The surface uses anode oxidation 12-15mic. Excellent

anti-corrosive rust and anti-rust performance ensures its 30-year

service life. At the same time, the characteristics of aluminum

lightweight reduces the weight of the roof and make it safe and

reliable. The maximum wind speed can carry 60m/s, and the snow load

capacity is 1.4kn/㎡.

All

bracket solutions of Corigy are calculated based on the live conditions

environment. Corigy's advanced technical team conducted a force

analysis of the structure of the building, combined with the layout of

the bracket and photovoltaic components to verify the various feasible

bracket installation solutions to determine the most efficient,

convenient, safe and reliable solution.